How Does A Concrete Batching Plant Work?

Dec 31, 2024

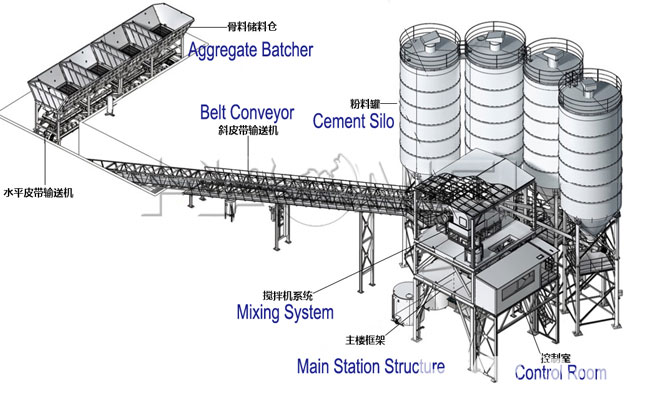

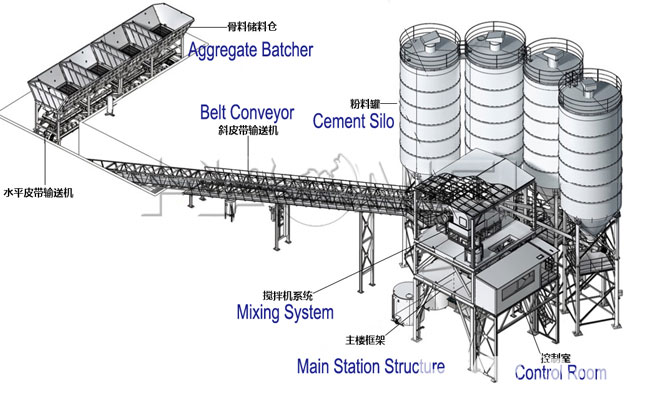

How does a concrete batching plant work is a systematic process that involves several links, from the preparation of raw materials to the transportation and pouring of the final concrete.

The following is a detailed description of how does a concrete batching plant work:

1. Preparation of raw materials

1.1 Types of materials

- Cement: usually stored in cement silos and transported using pneumatic or screw conveyors.

- Aggregate: including sand and gravel, usually divided into coarse aggregate and fine aggregate, stored in different silos.

- Water: is automatically conveyed through a plumbing system.

- Additives: such as water reducers, air-entraining agents, etc., which are usually added by means of special metering devices.

1.2 Storage

All raw materials need to be stored in specialized storage silos or tanks to keep them dry and clean.

2. Metering

2.1 Automatic metering system

Modern concrete batching plants are usually equipped with advanced automatic metering systems that can accurately measure the amount of each raw material according to the requirements of the concrete recipe.

Metering is usually categorized into gravimetric and volumetric metering, with gravimetric metering being more common as it provides a higher degree of accuracy.

2.2 Metering Process

Under the command of the control system, the system will meter the cement, aggregate, water and admixture in sequence. After the metering of each material is completed, the system will be calibrated to ensure the accuracy of the metering.

3. Mixing

3.1 Types of Mixers

Different types of concrete mixers can be used in the

concrete mixing plant, mainly:

- Forced concrete mixer: suitable for high-strength concrete with uniform mixing and high efficiency.

- Self-falling mixer: suitable for ordinary concrete with wide applicability.

3.2 Mixing process

Feed the measured raw materials into the mixer and start the concrete mixer for mixing. The mixing time and rotating speed will be adjusted according to the formula and requirements of the concrete, usually between 30 seconds and a few minutes.

During the mixing process, the blades of the mixer will keep turning and cutting the raw materials to make them fully mixed and reach a homogeneous state.

4. Transportation

4.1 Concrete Transportation Truck

After mixing, the concrete will be transported to the mixing transportation vehicle, which is equipped with a rotating mixing drum to keep the concrete fluid during transportation.

4.2 Transportation process

During transportation, the drum of the concrete mixer truck rotates continuously to prevent separation and solidification of the concrete. The transportation time is usually controlled within 2 hours to ensure the quality of the concrete at the time of use.

5. Discharging

5.1 Discharge Method

After arriving at the construction site, the concrete will be discharged through the discharge opening, and the common discharge methods are:

- Direct Discharge: Pour the concrete directly into the construction area.

- Pumping: Concrete pumps are used to transport the concrete to distant or high construction locations.

5.2 Discharge management

In the process of discharging, it is necessary to pay attention to the fluidity and uniformity of concrete to ensure the quality of pouring.

6. Cleaning and Maintenance

6.1 Cleaning

After use, the concrete mixer and conveying equipment need to be cleaned in time to prevent the concrete residue from drying out and affecting the next use. Cleaning is usually done with a high pressure water jet to ensure that all concrete residue is removed.

6.2 Regular Maintenance

Regular maintenance and servicing of the concrete batching plant equipment includes checking the electrical system, mechanical components and hydraulic system to ensure proper operation and prolong the service life of the equipment.

7. Control system

Modern concrete batching plant is equipped with automated control system, including touch screen operation interface, which can monitor the production process in real time, record the production data, and carry out formula management and quality control.

Through the above steps, the concrete batching plant can efficiently and accurately produce concrete that meets the requirements of the project and meets the needs of the construction project. With the development of science and technology, the degree of automation and production efficiency of the concrete batching plant is also improving.

(Chat Online)

(Chat Online)