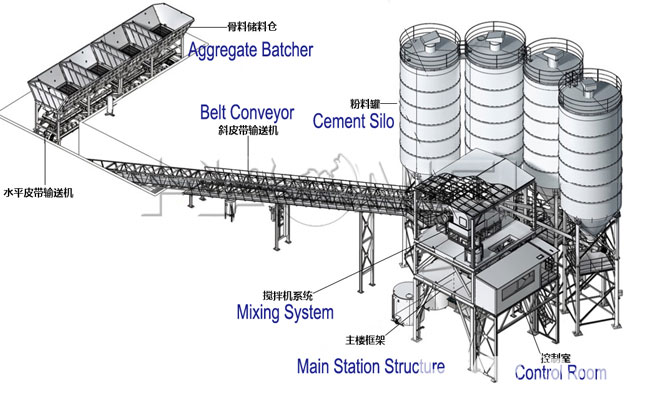

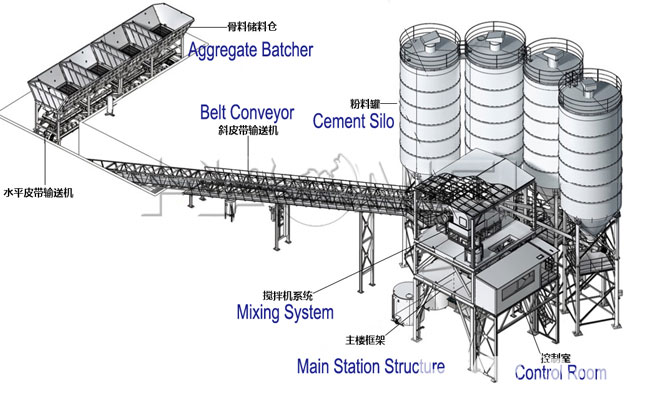

Components of RMC Plant

Jun 24, 2025

Rmc plant equipment is a complete set of equipment for centralized mixing of concrete. Its components usually cover multiple functional modules such as raw material storage, metering, mixing, and control systems.

The following is a detailed components of rmc plant:

1. Raw material storage system

- Cement silo

It is used to store powdered raw materials such as cement and fly ash. It is generally a cylindrical steel structure, equipped with a level meter to monitor the inventory, a dust removal device on the top to prevent dust from overflowing, and an arch breaking device at the bottom to prevent raw materials from agglomerating.

- Aggregate silo

Store aggregates such as sand and stone, mostly in separated silos (usually divided into 3-6 silos), which can be stored according to different particle sizes. A discharge gate or belt conveyor is installed at the bottom of the silo to facilitate raw material transportation.

- Water and admixture storage tanks

Water storage tanks are generally made of stainless steel or concrete structures. Admixture storage tanks need to be made of anti-corrosion materials according to the characteristics of the agent. They are all equipped with level meters and delivery pumps.

2. Measuring system

- Aggregate metering

Use belt scale, electronic scale or cumulative scale to weigh sand and stone aggregates in real time through sensors, with an accuracy of ±2% to ensure accurate mix ratio.

- Powder metering

Cement, fly ash, etc. are transported from silos to metering buckets through screw conveyors and measured with electronic scales, with an accuracy requirement of ±1%.

- Water and admixture metering

Water is measured by flow meters or metering pumps, and admixtures are measured by volume or weighing, with an accuracy of ±1%.

3. Mixing system

Mixer

Core equipment, common types include:

- Forced mixer: suitable for commercial concrete mixing, forced mixing of aggregates, cement and water through blades, high mixing efficiency and good uniformity, divided into vertical shaft type and horizontal shaft type (such as double horizontal shaft mixer).

- Free-fall mixer: less used in premixing plants, mainly relying on the weight of the material to fall and mix, suitable for low-strength concrete.

The capacity of the mixer is selected according to the production capacity (such as 1.5m³, 2m³, 3m³, etc.), equipped with wear-resistant lining and mixing blades for easy maintenance and replacement.

4. Conveying system

- Aggregate conveying

Belt conveyor: convey aggregate from the silo to the measuring bucket. When conveying at an angle, a baffle must be installed to prevent the material from sliding.

Elevator: Some stations use bucket elevators to convey aggregate vertically.

- Powder conveying

Screw conveyor: convey cement and fly ash from the silo to the measuring bucket, with good sealing to avoid dust leakage.

Pneumatic conveying: convey powder to the designated location through compressed air, suitable for long-distance conveying.

- Concrete conveying

Mixer truck: the finished concrete is loaded into the mixer truck through the discharge chute and transported to the construction site.

5. Control system

Central control room

Integrated PLC control cabinet, industrial computer, display screen, etc., through special software (such as concrete mixing station management system) to achieve full process automation control, including:

Precise control of raw material metering, mixing time, and unloading sequence;

Mix ratio setting, production data recording, fault alarm;

Interconnection with ERP system to achieve production scheduling and quality traceability.

6. Auxiliary system

- Dust removal system

Bag dust collectors are installed at dust emission points such as silo top and mixing host to reduce environmental pollution and meet environmental protection requirements.

- Wastewater recovery system

Wastewater from washing mixers and vehicles can be reused in concrete production after being treated in sedimentation tanks, saving water resources.

- Exhaust gas treatment

Exhaust gas from equipment such as diesel generators is discharged after purification.

- Safety protection devices

Including lightning protection devices, fire protection facilities, equipment overload protection (such as motor overload shutdown), operation safety warning signs, etc.

7. Other supporting equipment

- Laboratory equipment

Used for raw material testing (such as aggregate grading, cement strength) and concrete performance testing (slump, compressive strength) to ensure product quality.

- Vehicles and auxiliary machinery

Loaders (loading aggregate silos), concrete mixers, pump trucks (concrete delivery), weighbridges (raw material weighing), etc.

The ready mix concrete plant realizes fully automated production from raw material storage, metering, mixing to finished product delivery through the coordinated operation of various systems. Its equipment configuration needs to be customized according to production capacity requirements (such as HZS60, HZS180 and other models, the numbers represent theoretical capacity per hour), site conditions and environmental protection standards to ensure concrete quality and production efficiency.

(Chat Online)

(Chat Online)