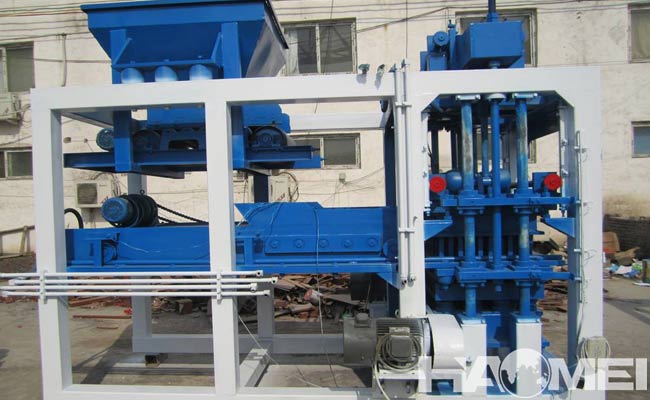

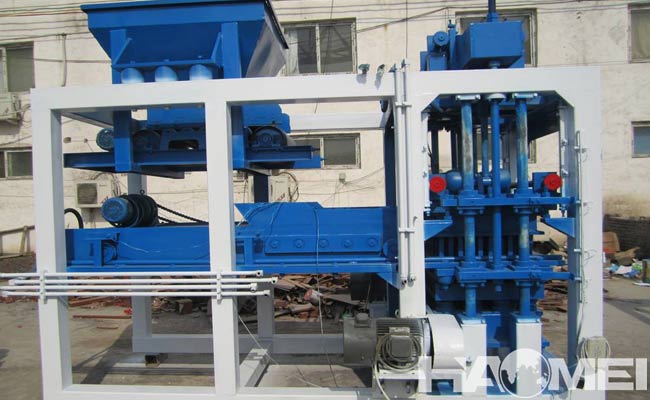

Cement Brick Moulding Machine

Jun 13, 2024

Cement brick moulding machine is a kind of equipment specially used for producing cement blocks. With twin shaft concrete mixer, hydraulic press and uniform vibration, the produce cement bricks are with high quality, strong structure, accurate size and protect moulds.

The cement brick moulding machine is composed of the following parts:

1. hopper: a hopper for storing the mixed cement, sand and other raw materials.

2. Mixer: to mix the raw materials to ensure the uniform quality of the molded bricks.

3. Molds: different shapes and sizes of molds can be changed as needed for molding cement bricks.

4. Vibration system: Vibrating inside the mold to make the raw materials fill the mold fully and remove the air bubbles, so as to improve the denseness of the bricks.

5. Hydraulic system: Provide pressure to make the raw material forming and curing in the mold.

6. PLC control system: Control the whole production process, including mixing, molding, vibration, pressure and other parameters adjustment and monitoring.

Working principle of

cement brick making machine:

1. Put the pre-mixed cement, sand and other raw materials into the hopper.

2. The hopper conveys the raw materials to the mixer for full mixing.

3. The mixed raw materials are transported to the mold through the conveyor belt.

4. The vibration system starts working and vibrates the raw materials in the mold to ensure that they are well filled and air bubbles are eliminated.

5. The hydraulic system applies pressure to form and cure the material in the mold.

6. After the molding is completed, the mold is opened and the molded bricks are taken out for subsequent processing and maintenance.

Advantages of cement brick moulding machine:

1. High degree of automation, high production efficiency, saving labor cost.

2. The quality of the molded bricks is stable, with high compactness and good compressive strength.

3. Molds can be changed as required, suitable for the production of blocks of different shapes and sizes.

4. Simple operation, PLC control system is convenient to operate and monitor the whole production process.

5. The vibration frequency and pressure can be adjusted according to the needs, adapting to different raw materials and molding requirements.

(Chat Online)

(Chat Online)