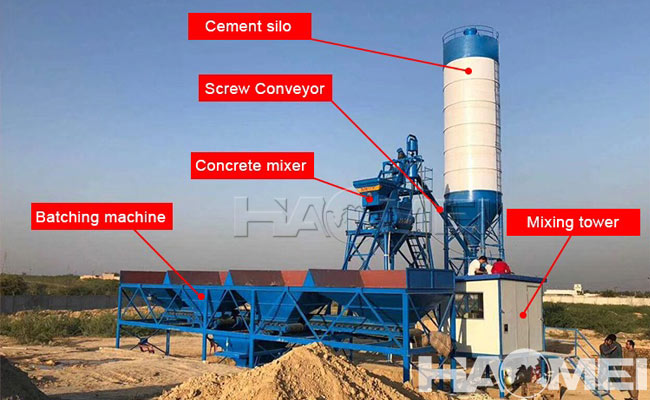

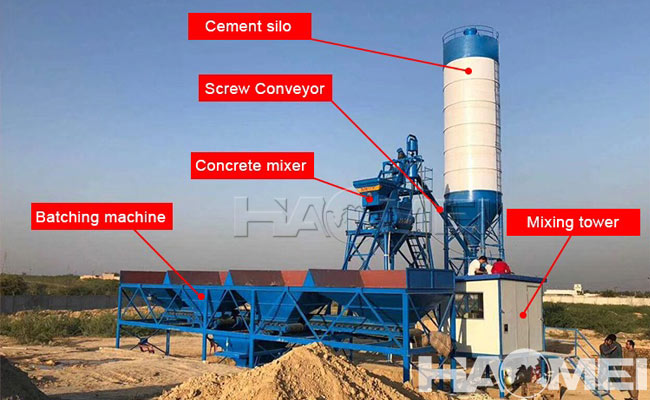

Concrete Batching Plant Components

Jul 09, 2024

A concrete batching plant usually consists of several key components that work in tandem to ensure efficient, high-quality production of concrete.

Below are the details of concrete batching plant components:

1. Mixing host

Role: The mixing host is the core equipment of the concrete mixing plant, responsible for fully mixing and blending the raw materials such as cement, aggregate (sand, stone, etc.), water, additives, etc. to form the concrete that meets the requirements.

Types: Commonly used concrete mixing machines include double horizontal shaft forced concrete mixer, vertical concrete mixer, planetary concrete mixer, etc. Among them, double horizontal shaft forced concrete mixer is widely used because of its strong mixing capacity, low energy consumption, long service life and other advantages.

Characteristics: The mixing host is designed with reasonable mixing blades and mixing arms, which can ensure that the concrete is evenly mixed during the mixing process, and at the same time reduce the mixing time and energy consumption.

2. Material weighing system

Role: Material weighing system is a key component affecting concrete quality and production cost. It is responsible for accurately weighing all kinds of raw materials to ensure the accuracy of concrete proportion.

Composition: The material weighing system is mainly divided into three parts: aggregate weighing, powder weighing and liquid weighing. The weighing accuracy is usually very high, such as aggregate weighing accuracy of ≤2%, cement, powder, water and additives weighing accuracy of ≤1%.

Characteristics: Modern concrete batching plant mostly adopts electronic scale and microcomputer control, which improves the weighing precision and automation level.

3. Material conveying system

Role: The material conveying system is responsible for conveying all kinds of raw materials from the storage equipment to the mixing machine.

Composition: It includes aggregate conveying system, powder conveying system and water conveying system.

Aggregate conveying system: mainly composed of belt conveyor, bucket elevator, vibrating screen, etc., used for conveying sand, stone and other aggregates.

Powder conveying system: mainly consists of powder storage tank, powder pump, powder conveying pipeline and so on, used for conveying cement, fly ash and other powder materials. Screw conveyor is one of the commonly used conveying methods.

Water conveying system: mainly consists of pool, pump, water pipe, etc., used to convey water into the mixing host.

4. Water supply system

Role: The water supply system is responsible for providing the required water resources for the mixing process.

Composition: It includes living water system and production water system. The production water system is mainly used for aggregate washing and equipment cooling in the process of concrete mixing.

5. Electrical control system

Role: The electrical control system is the control center of the concrete mixing plant, responsible for the automatic control of the whole mixing plant.

Composition: It is mainly composed of programmable controller (PLC), touch screen, frequency converter, sensors and so on. Through the electrical control system, remote monitoring, automatic adjustment, fault diagnosis and other functions of the mixing plant can be realized.

6. Auxiliary equipment

Role: Auxiliary equipment is used to improve the production efficiency and automation level of the concrete mixing plant, to ensure production safety and to meet specific construction needs.

Common equipment: including admixture pumps, mortar pumps, plug valves, dust collectors and so on. Admixture pumps and mortar pumps are used to add admixtures and mortar to the concrete; plug valves are used to control the flow of materials; and dust collectors are used to minimize the dust pollution generated during the mixing process.

Overall, the various concrete batching plant components work closely together to complete the concrete production process and ensure production efficiency and concrete quality. Different sizes and models of concrete batching plant may vary in the design and configuration of each component, but the components listed above are its basic components.

(Chat Online)

(Chat Online)